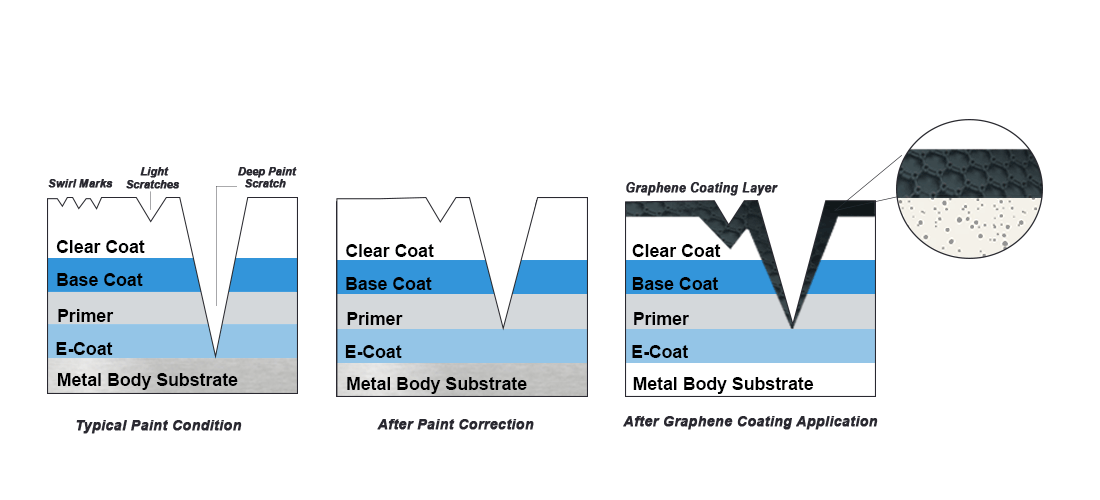

Graphene Coating also known as “Nano Graphene” Coating is a formulation of liquid nanometer-size Graphene particles (an Allotrope of Carbon!!) which is uniformly applied all over the surface by hand using applicator pads and then hand-buffed using a microfiber towel. Automatic Polishers are usually avoided for the application of graphene coatings to prevent wastage. Due to the similarity in both application & curing methods as well as the coating results between Graphene Coatings and SiO2-based Ceramic Coatings, Graphene Coating is often misconceived to be another form of Ceramic Coating. This is not true as Graphene coatings are a completely separate form of coatings that are composed of graphene as compared to ceramic coatings which are based on Silicon-di-Oxide (SiO2).

Now, what is Graphene you ask? Well, Graphene is the name for a single layer (monolayer) sheet of carbon atoms that are bonded together in a repeating pattern of hexagons. This sheet is only one atom thick. Monolayers of graphene stacked on top of each other form graphite. Since a typical carbon atom has a diameter of about 0.33 nanometers, there are about 3 million layers of graphene in a 1 mm thick sheet of graphite!!!

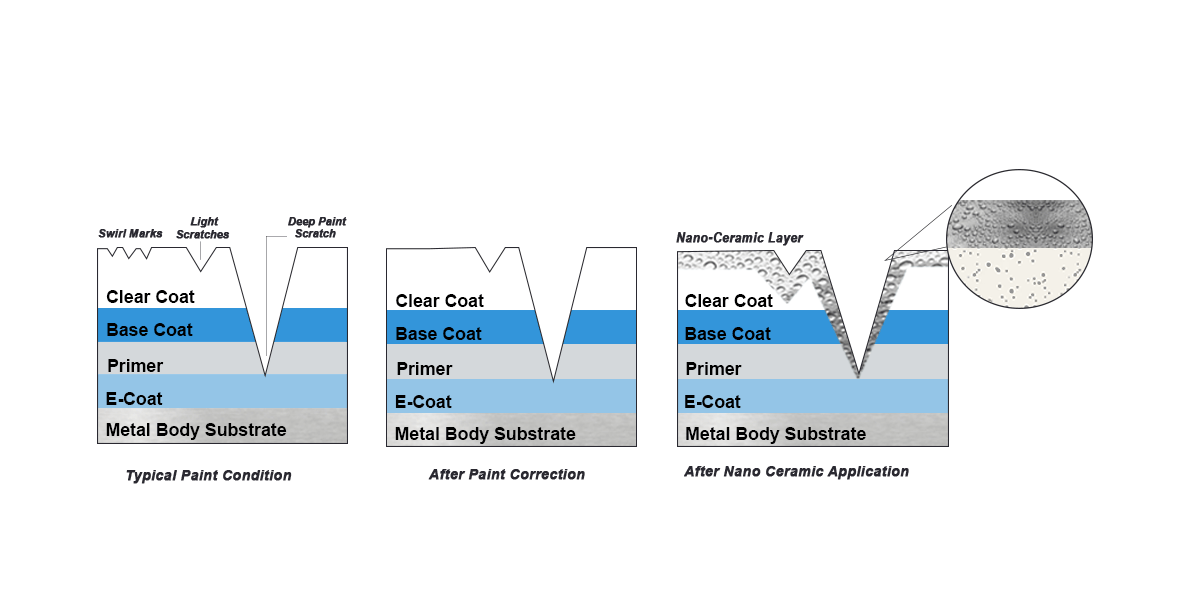

The coating is supposed to form an even layer all over the coated surface without changing the original thickness, texture, or feel of the coated body. An even layer of Graphene coating has a thickness of 1-2 microns maximum! For reference, the diameter of human hair is 70 microns!! As such Graphene coating protects your vehicle without any tangible change to the thickness and texture of your vehicle’s surface or body. Graphene coatings usually have a “Drying” phase and a “Curing” phase. It usually varies for the various coatings available in the market.

For more details on Graphene application and its curing read

Now 1mm = 1000 micron

And, a single layer of Graphene coatings is approximately 1 micron.

So, there are over 3,000 layers of graphene in a single layer of Graphene Coatings!!!!

Harder than diamond yet more elastic than rubber; tougher than steel yet lighter than aluminum – graphene is the strongest known material.

To put this in perspective: if a sheet of cling film (like kitchen wrap film) had the same strength as a pristine single layer of graphene, it would require the force exerted by a mass of 2,000 kg, or a large car, to puncture it with a pencil.